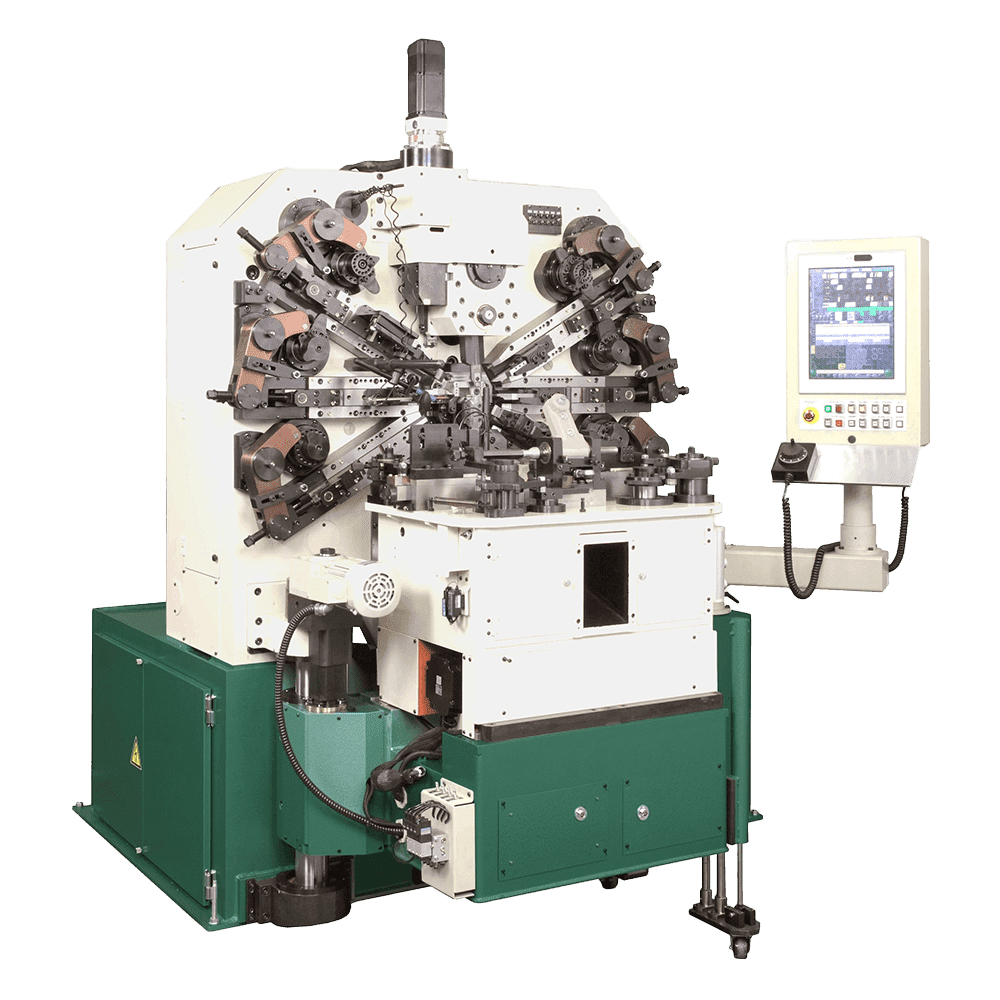

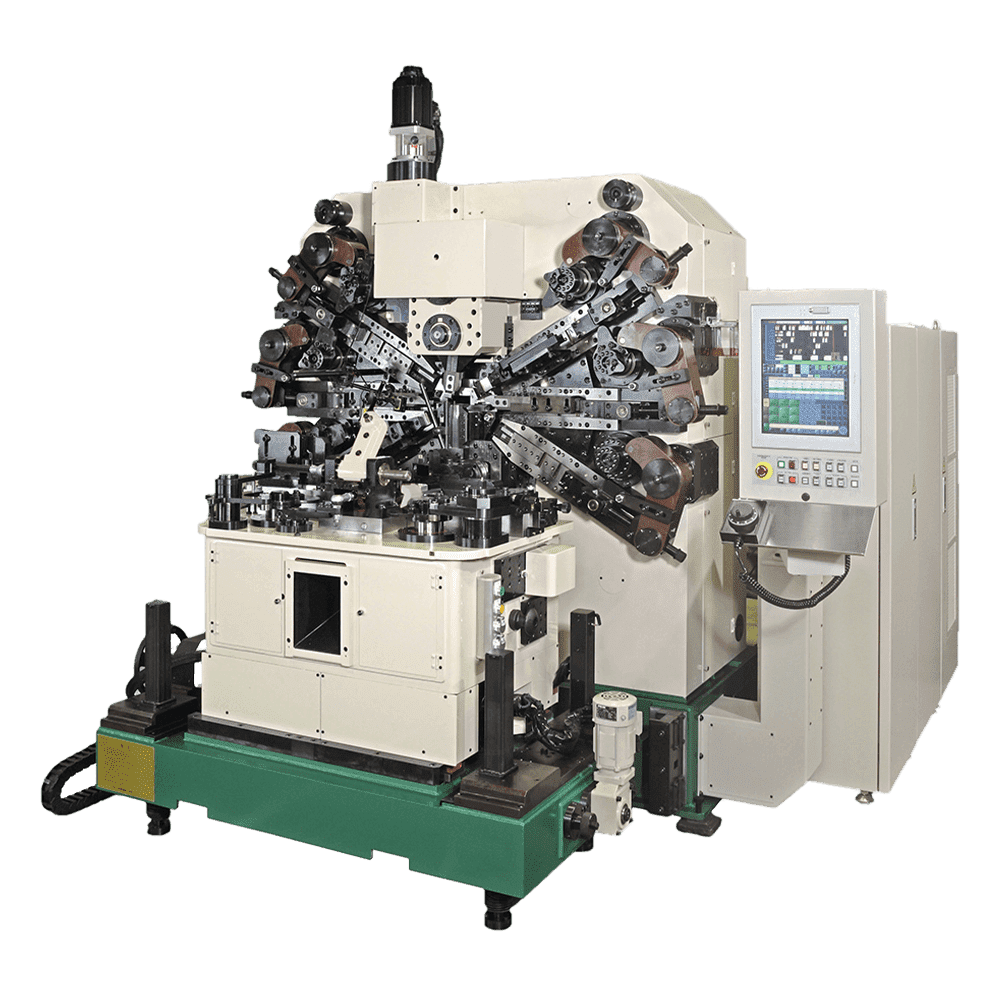

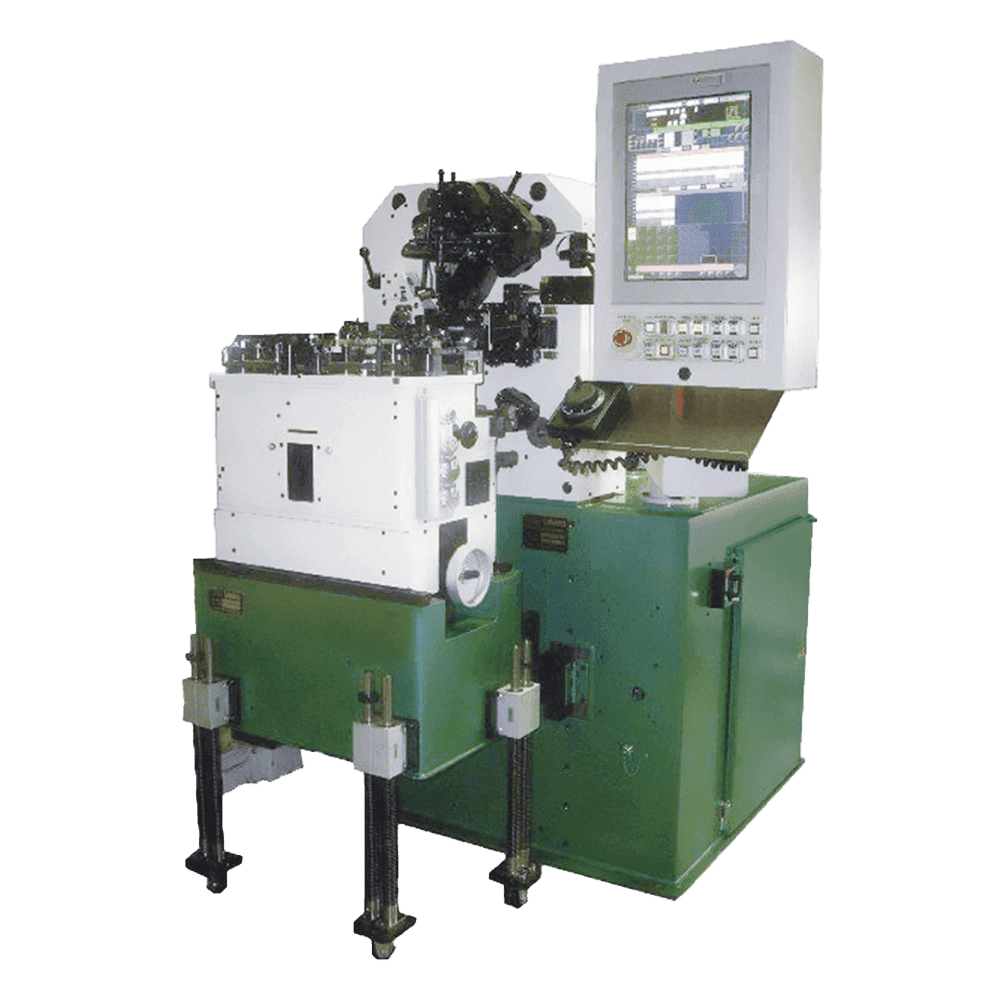

TF series

3D torsion attachment with combined optimum structure and CNC technologies for high-precison,

high-speed and

valu-added extension spring making.

Advantages of spring machine specialized to extension springs

- ・Valuable coiling functions

- ・Possibility to various shapes of hooks

- ・High speed production

- ・Wide manufacturing space

- ・Tools and spring-making methods with accumulated know-hows

- ・Progress with CNC technologies from VF800MFT series

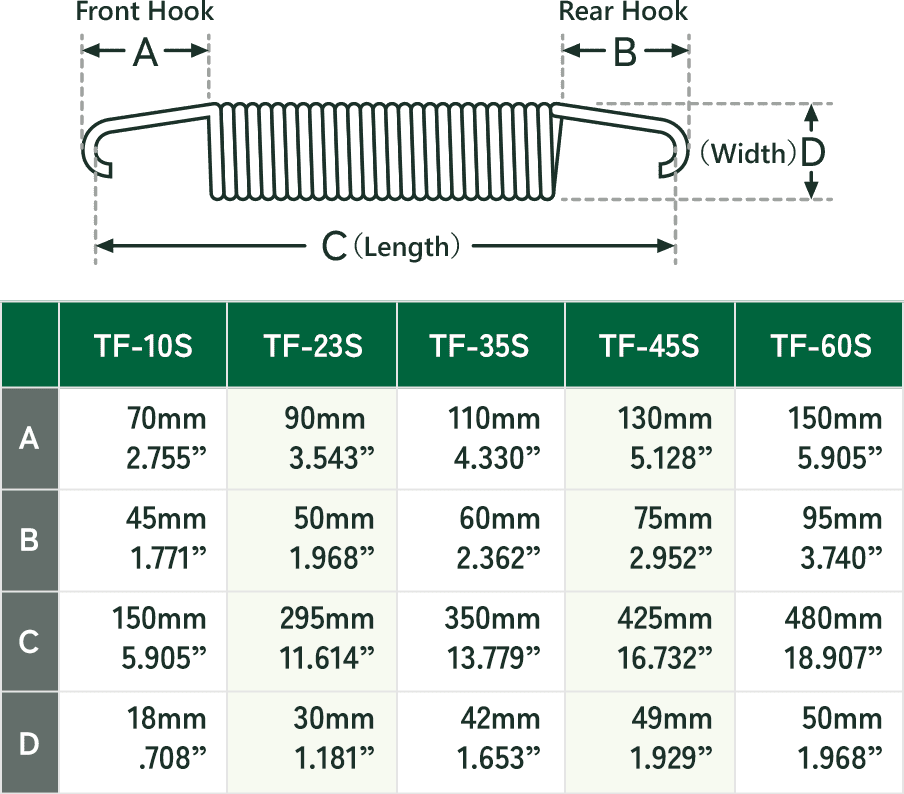

SPECIFICATIONS

| Model | TF-10S | TF-23S | TF-35S | TF-45S | TF-60S |

|---|---|---|---|---|---|

| Wire Diameter | 0.4mm~1.0mm .016"〜.039" |

0.6mm~2.6mm .024"〜.102" |

1.4mm~3.5mm .055"〜.137" |

2.0mm~4.5mm .079"〜.177" |

3.0mm~6.0mm .118"〜.236" |

| Max Feeding Speed | 90m/min | 90m/min | 90m/min | 120m/min | 120m/min |

| Servo Axis |

|

|

|||

| Weight | 1,000kg / 2,222lb. | 2,500kg / 5,555lb. | 3,300kg / 7,333lb. | 6,000kg / 13,333lb. | 8,500kg / 18,888lb. |

| Dimensions |

|

|

|

|

|

※Specifications can be changed without notice.

※TA = Torsion attachment

FEATURES

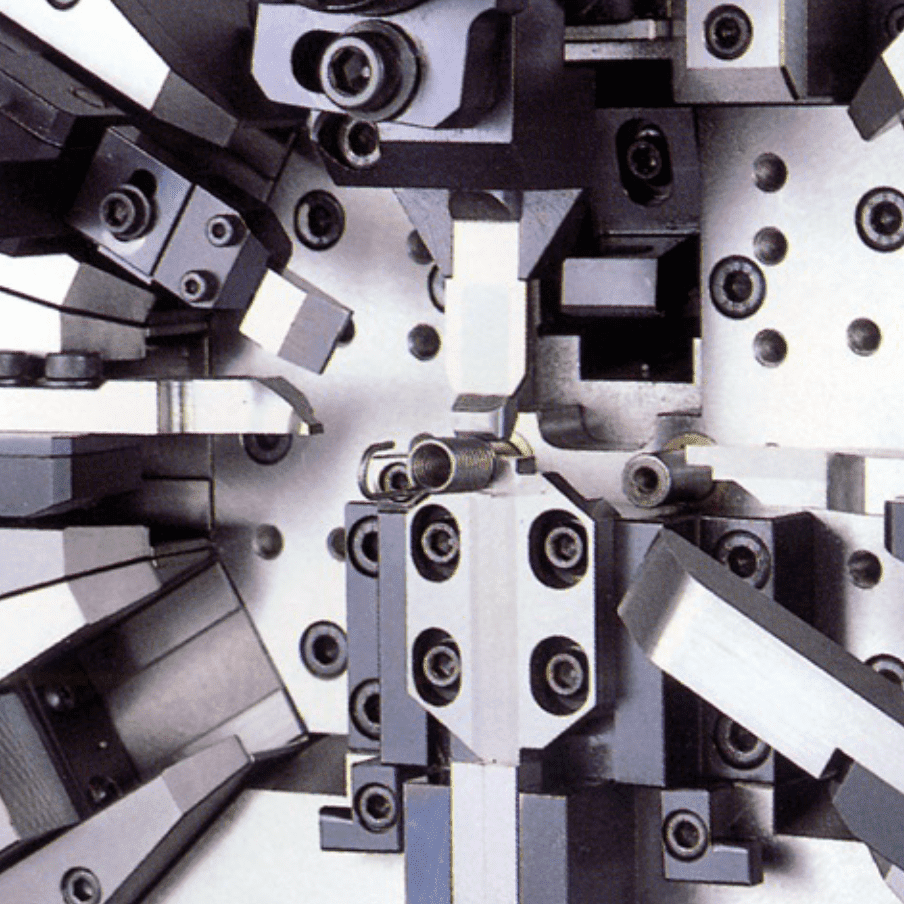

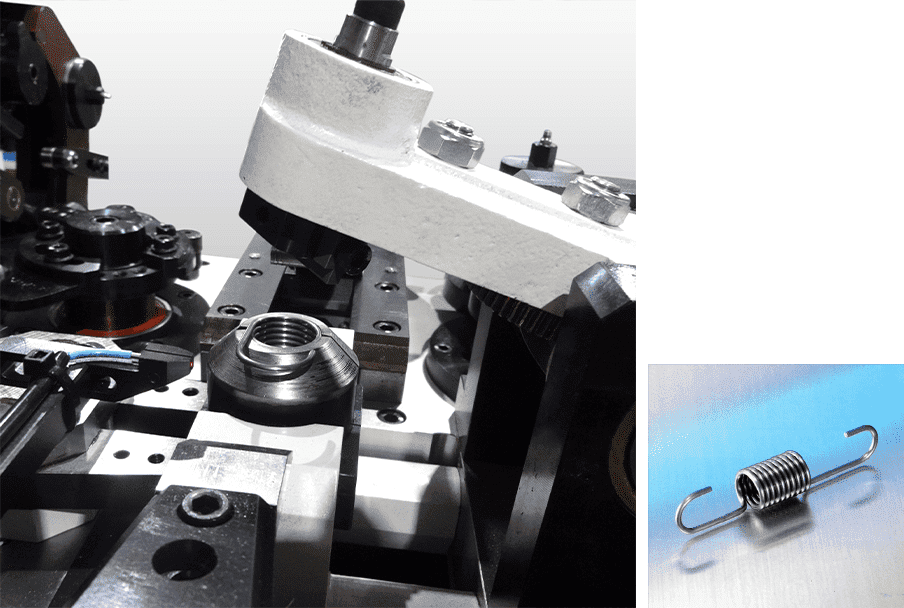

Valuable coiling functions

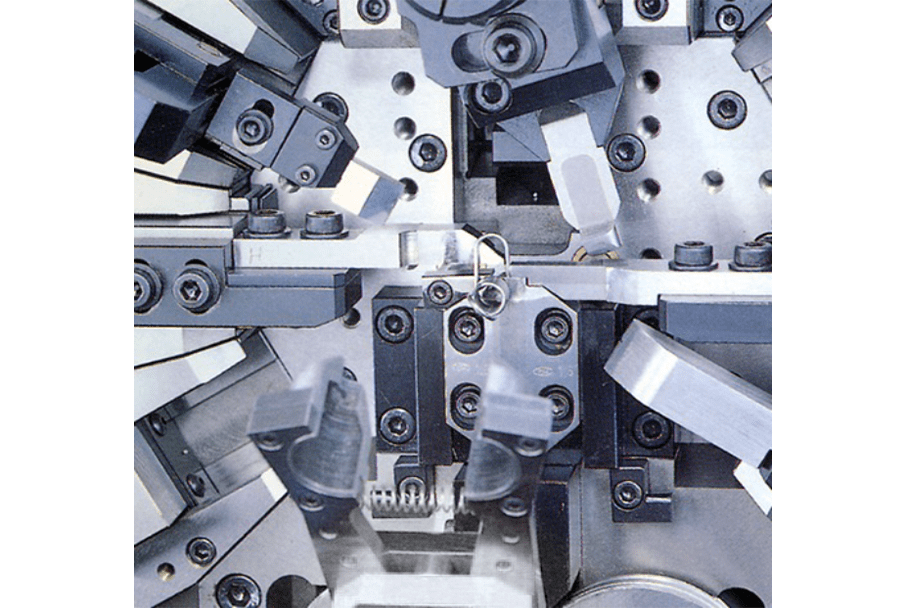

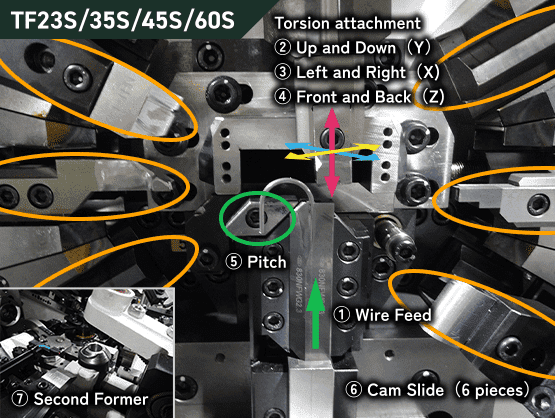

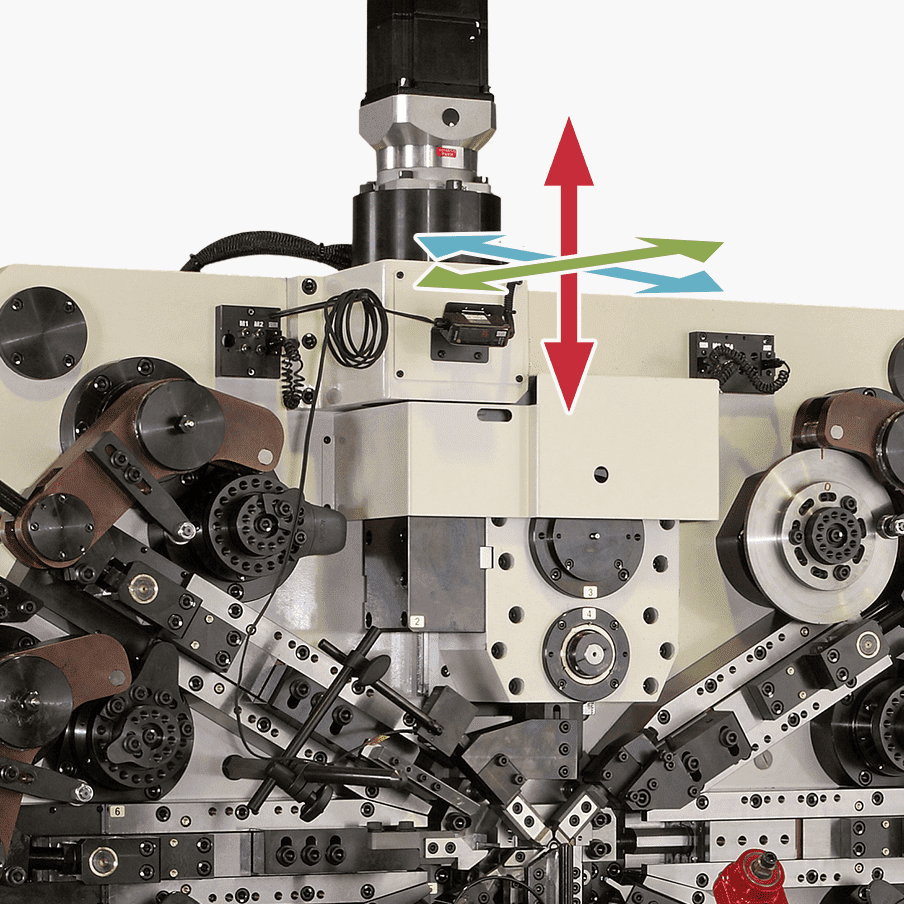

3D Torsion attachment

Torsion attachment to make hooks and body coiling moves in 3 dimensions

- X (horizontal): decides timing to make hooks and coiling.

- Y (vertical) : decides diameter of coiling

- Z (back and forth) : decides initial tension strength

Servo-controlled 3D torsion attachement is much easier to operate compared to that of VF800MFT series.

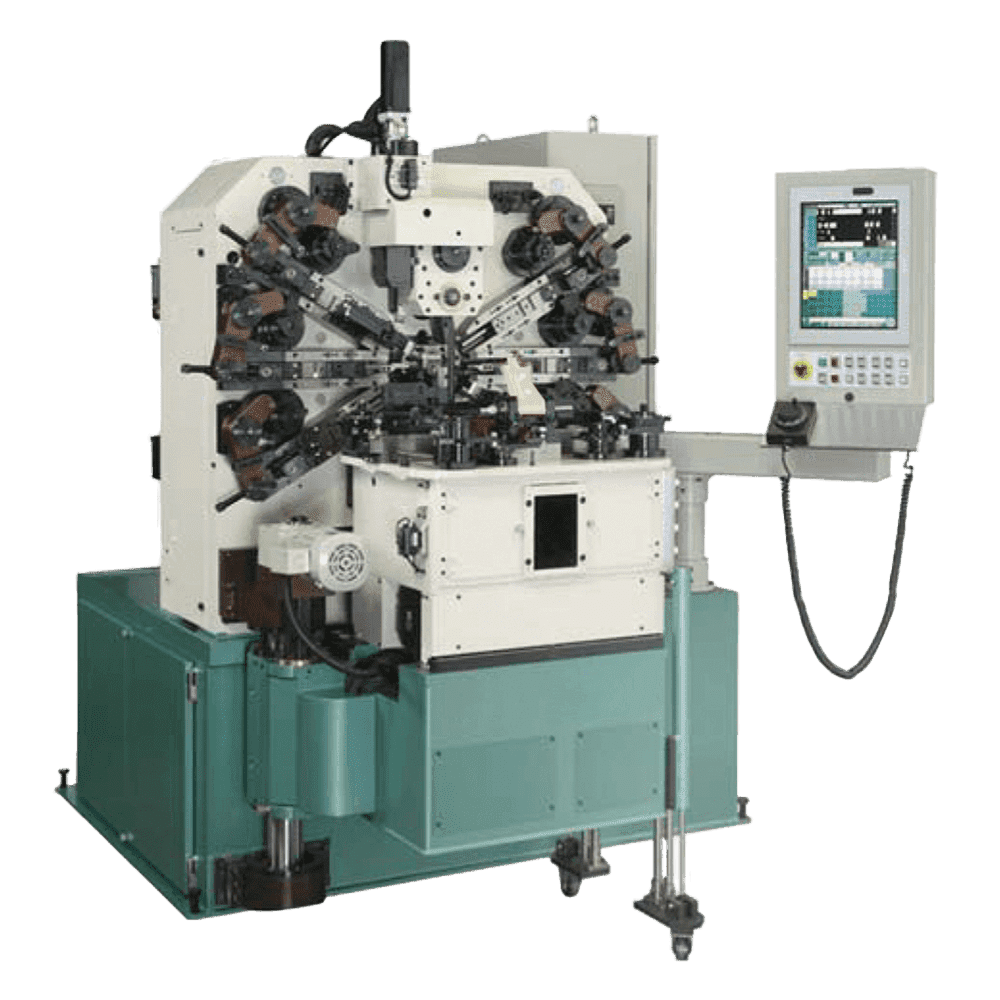

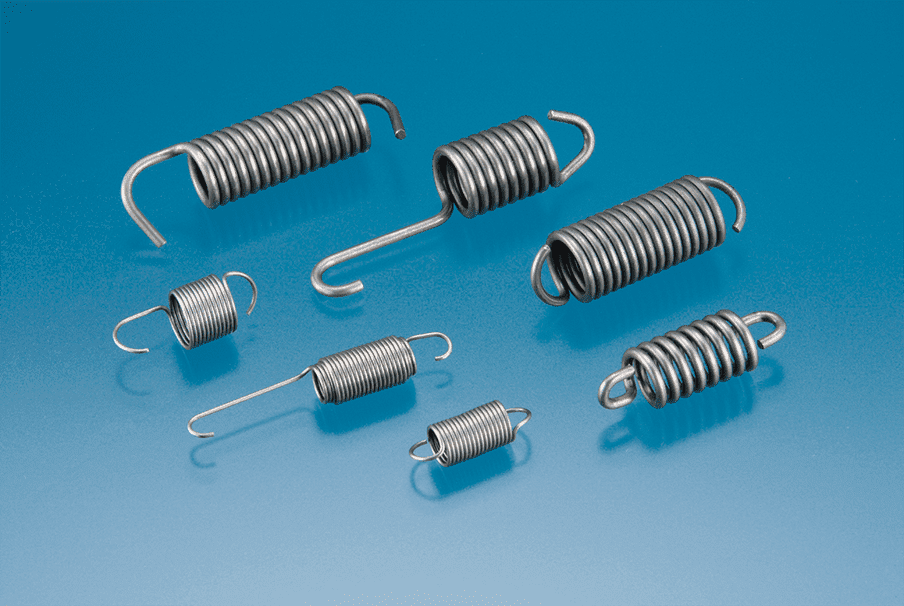

High-precision coiling with same line method

Power directions of wire feed and coiling point are on the same line, which makes

- ・High-precison coiling diameter

- ・Small index coiling

possible.*This method is the same principle as compression spring making.

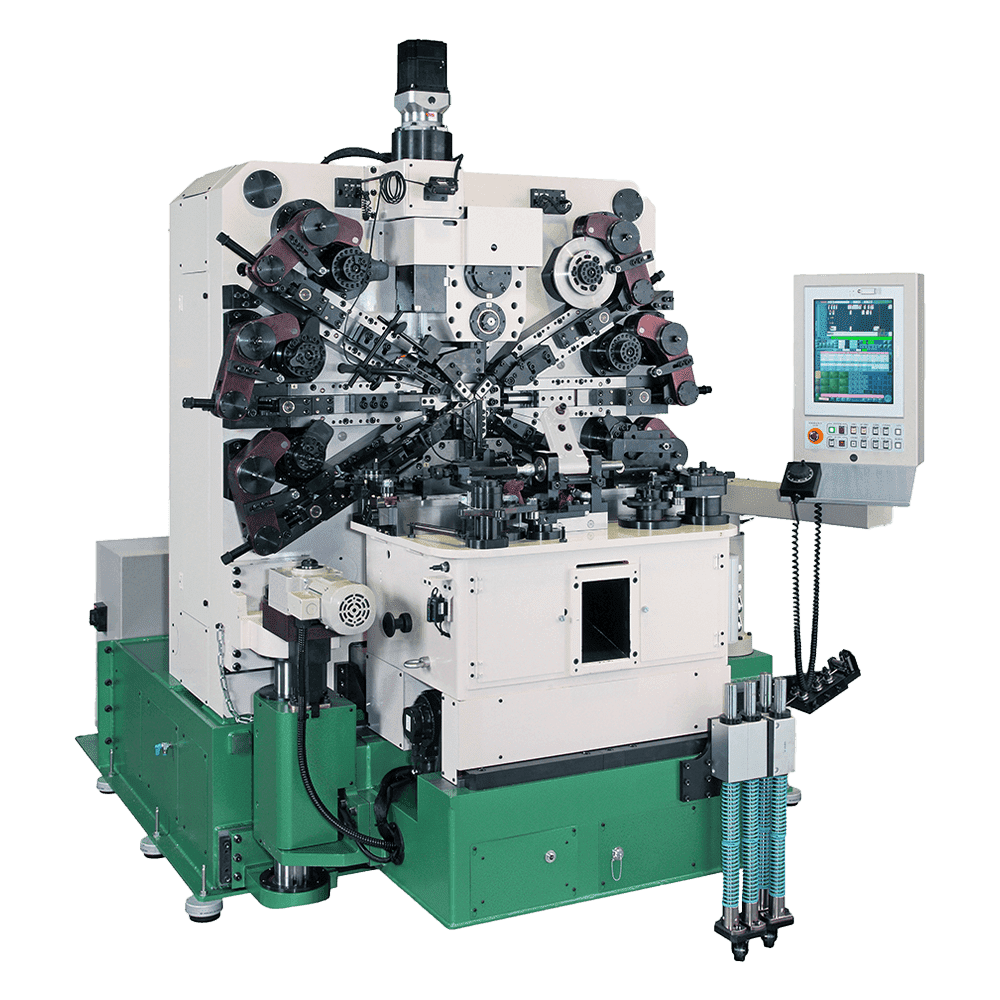

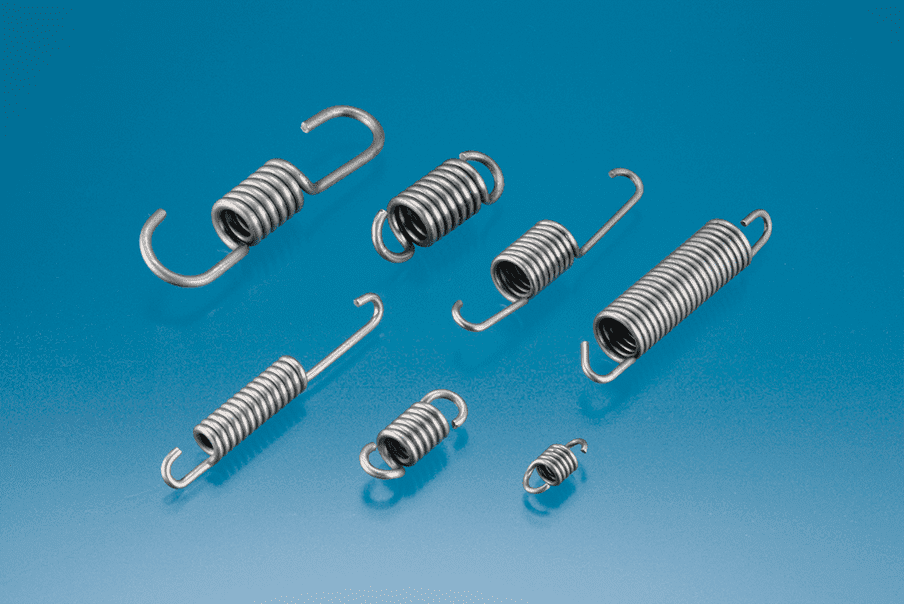

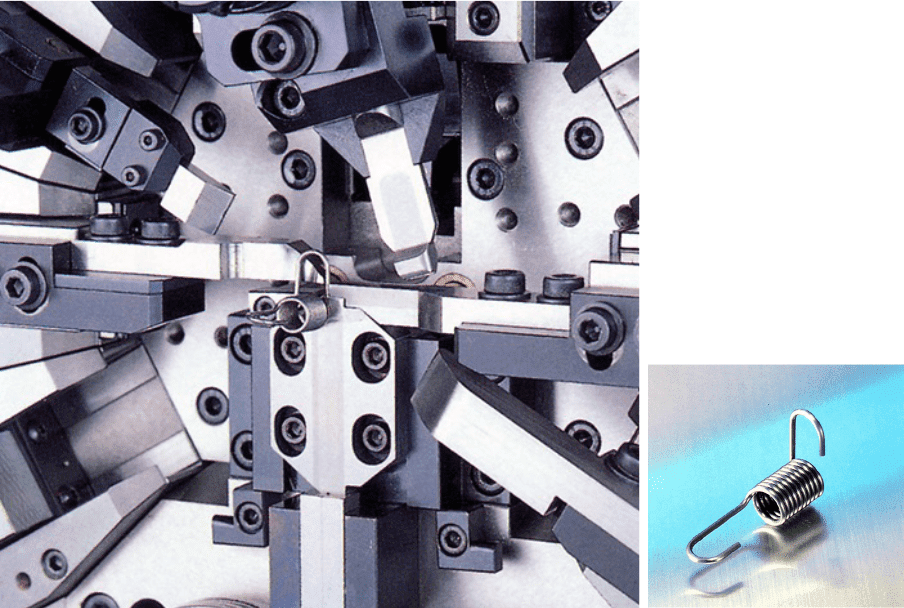

Various hook shapes

- ・English hook

- ・German hook

- ・Short end hook

- ・Long hook

- ・No-straight end hook

- ・Outside hook, Offset hook

- ・Smaller hook than coiling diameter

etc.

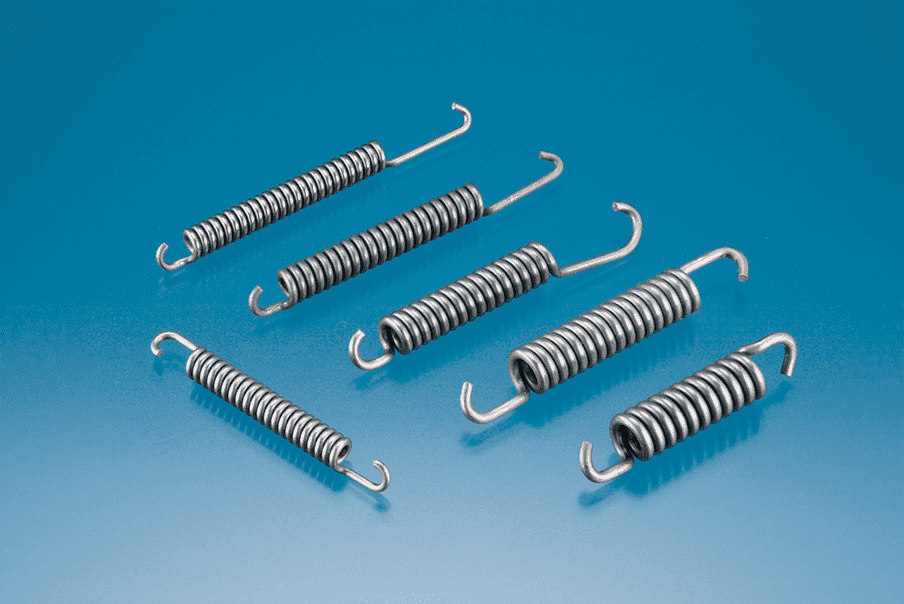

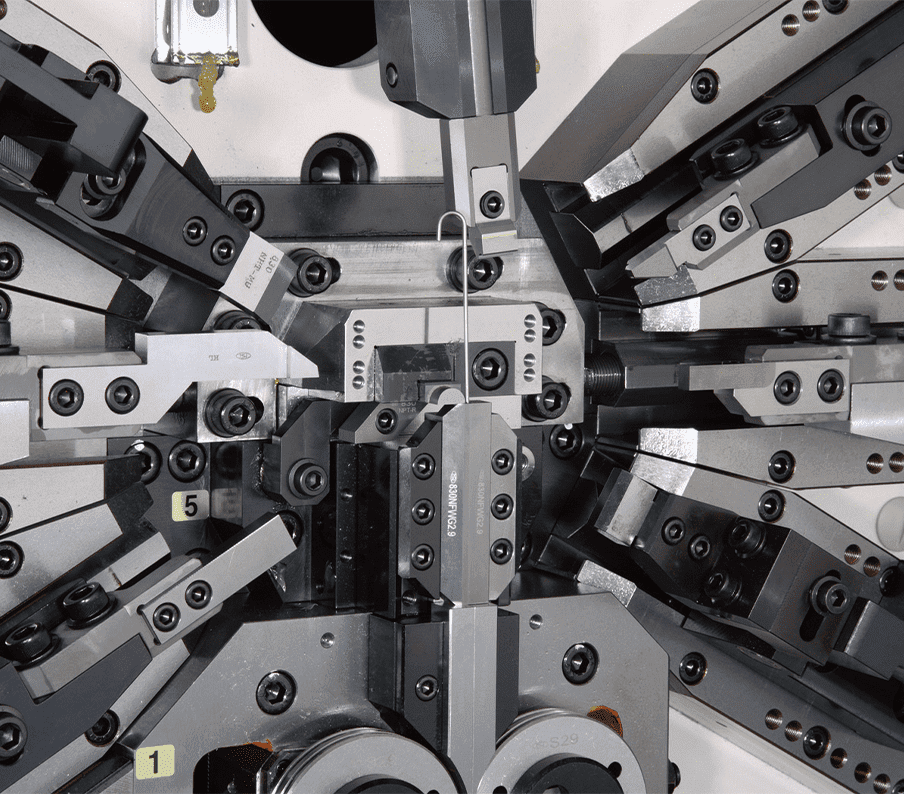

High speed production

- ①Main processing by Main machine

- ②Transfering to Second Former

- ③Processing by Second Former

During transfering a spring to Second Former, Main machine starts to make next spring for high speed production.

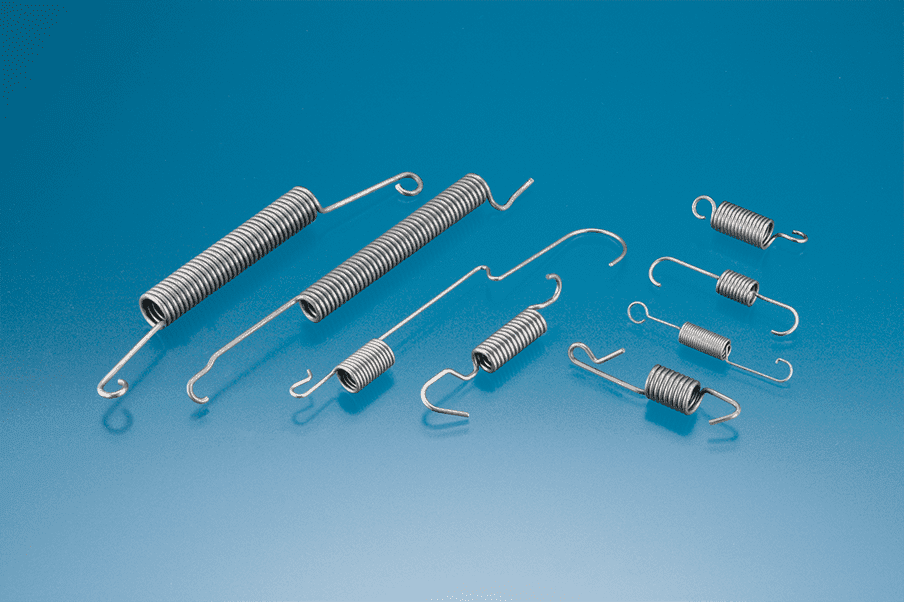

Wide manufacturing space

Both Main machine and Second Former have wide space optimum for long-coil springs and long-hook springs.

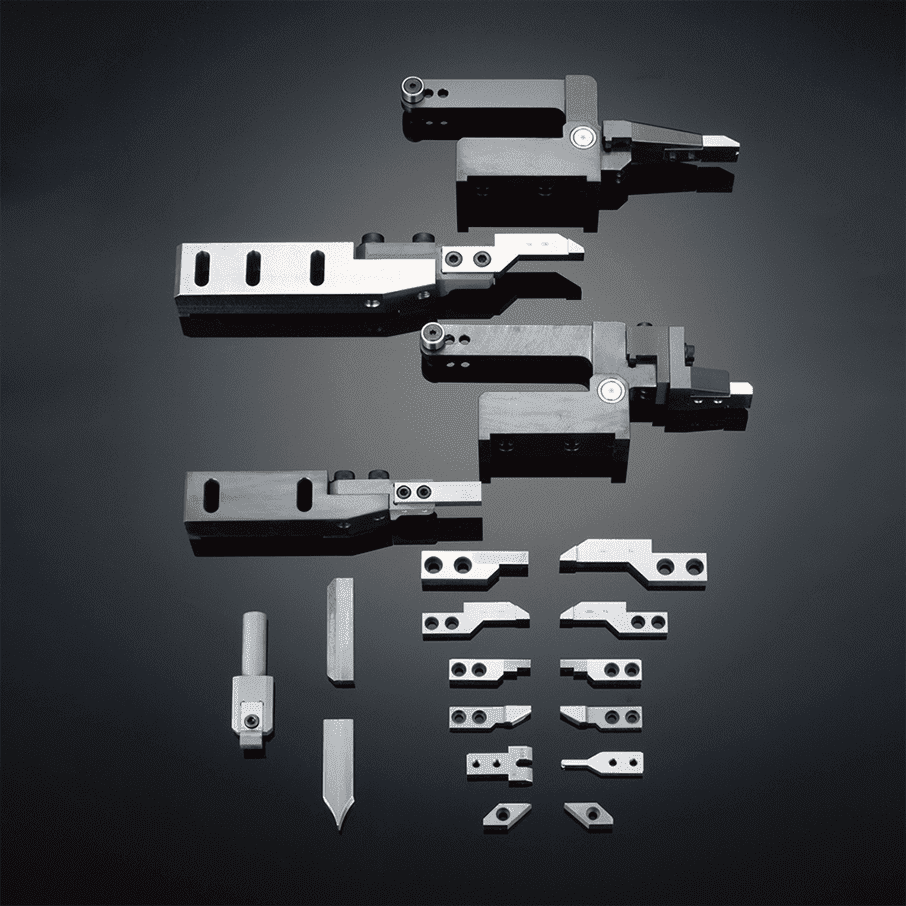

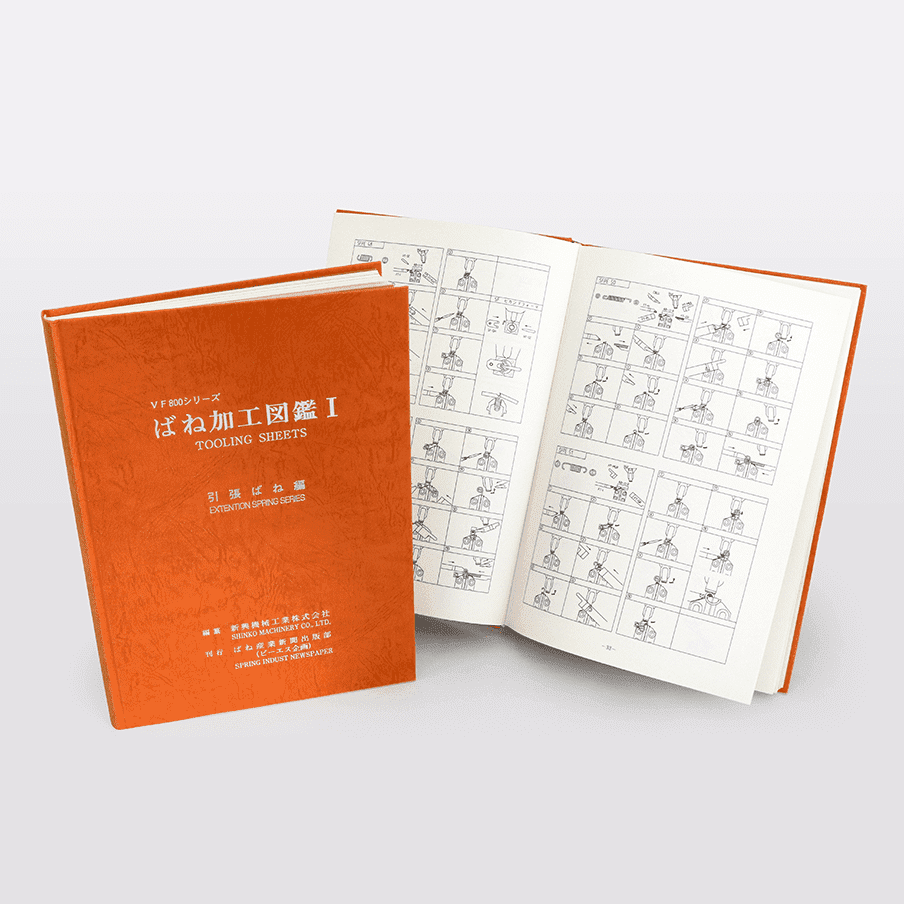

Accumulated processing know-hows

Various tools and manufacturing methods from accumulated processing know-hows for hook shapes, hook lifting and cutting, etc can make TF machine functions work to the full.

Progress from VF800MFT series

Servo-controlled torsion attachment and pitch without necessity of cam adjustment

Easier installing & detaching second former and its position adjustment.

Setting time is reduced by more than 50%.