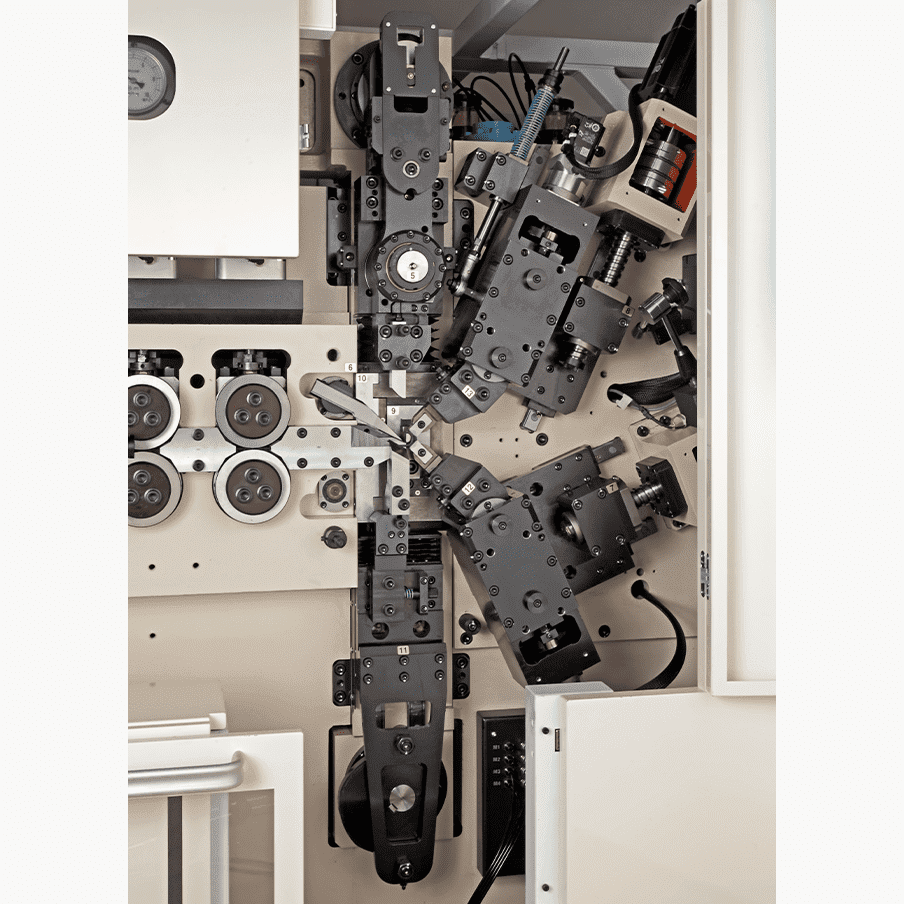

SPC-50

The ultimate in high-precision, high-speed,

long-term continuous production.

Part selection, design and structure pursuing

the optimum of compression spring processing elements.

A new frontier of coiling machines

also with excellent safety and operability

thanks to an integrated safety cover and new operation software.

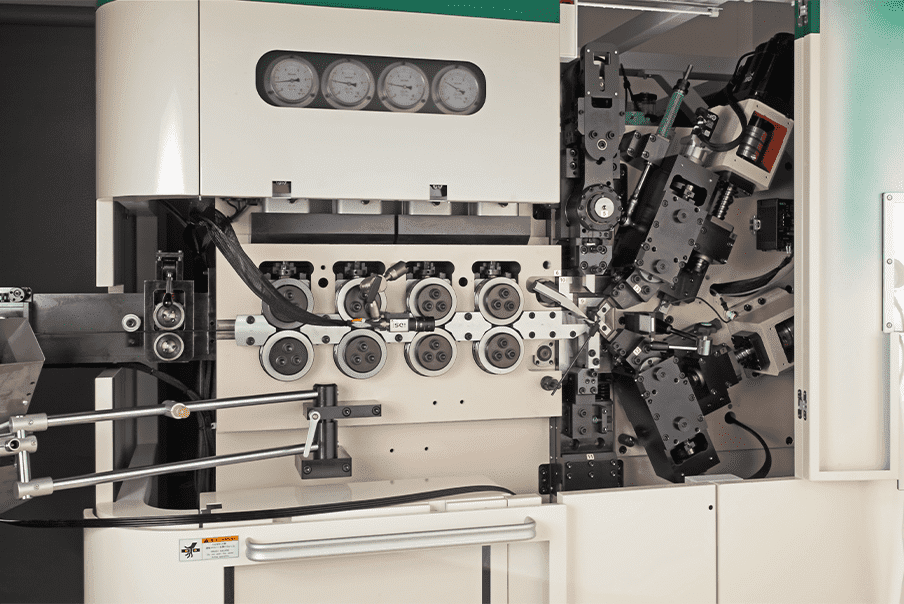

Ultimate coiling machine for highly precise springs and high speed production

- ・Design pursuing the optimum for each of wire feed, coiling, pitch, and cutting structure

- ・Parts selection and machine structure to realize high speed production

SPECIFICATIONS

| Model | SPC-50 |

|---|---|

| Wire Diameter | 2.0mm~5.0mm .078”~.196” |

| Max Feeding Speed | 180m/min |

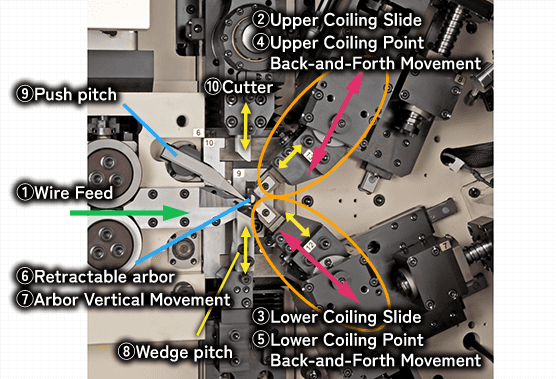

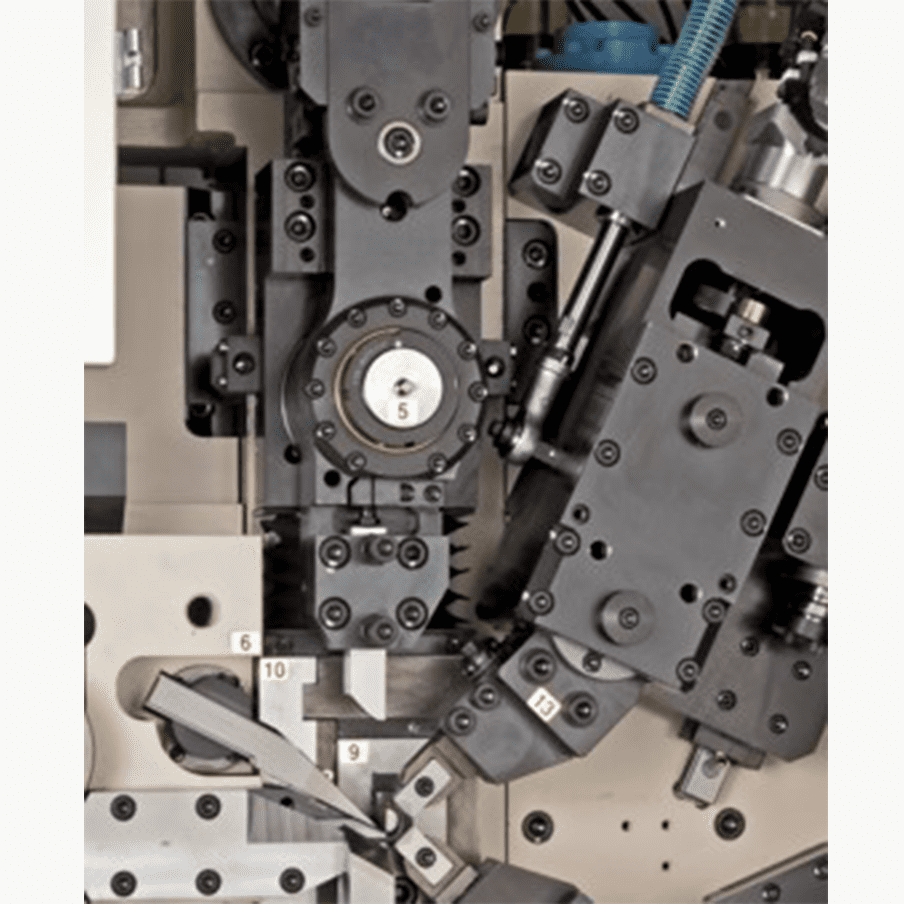

| Servo Axis |

①Wire Feed (one motor for each pair of upper and lower feed rollers) ②Upper coiling slide ③Lower coiling slide ④Upper coiling point back-and-forth ⑤Lower coiling point back-and-forth ⑥Retractable arbor ⑦Cutter and Arbor Box up and down ⑧Wedge pitch ⑨Push pitch ⑩Cutter |

| Weight | 3,700kg / 8,222lb. |

| Dimensions |

|

※Specifications can be changed without notice.

※SPC-50 is only for right hand coiling.

FEATURES

New concept coiling machine with detail consideration for high precision,

high speed and durability

Wire feed structure for excellent precision and durability

- ・One servo motor for each pair of feed rollers which brings precise wire feeding by refelcting servo-motor movement accurately to actual wire feed.

- ・The gear parts of the feed shafts are immersed in an oil bath, which saves the trouble of refueling, prevents gear wear, and achieves quiet operation.

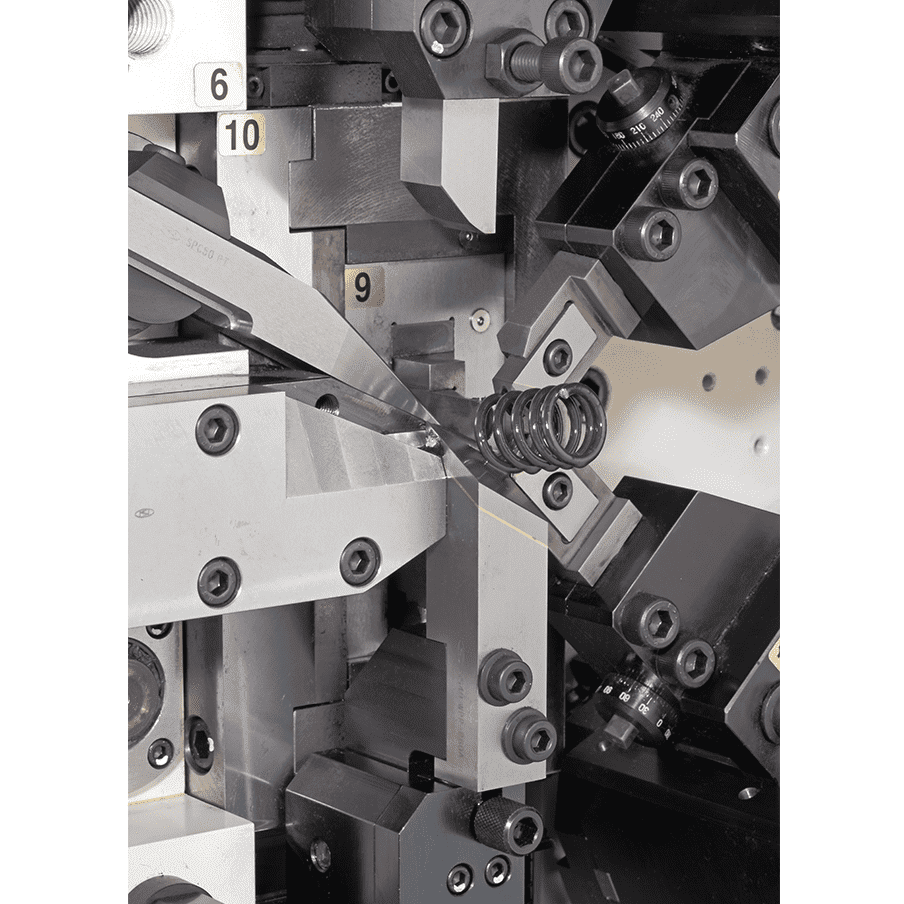

Highly precise coiling structure

- ・Right-hand only structure makes two slide coiling system possible, which can expand distance between two linear slides for stabler coiling point pisitioning.

- ・Both coiling points can move back and forth. Appropriate positining of the coling points for spring seats and pitch shapes.

Advanced pitch structure

- ・The push pitch is directly driven with a ball screw. In addition to positioning accuracy, excellent followability during high-speed production is realized.

- ・The lower slide is structured exclusively for wedge pitch for better performance and easier position adjustment.

Cutting structure for high speed and durability

- ・A tapered roller bearings are used as the fulcrum shafts for rotary cutter and cutting structure for strong impact resistance and high durability.

- ・750rpm cutting speed with high-speed servo motor and a timing belt.

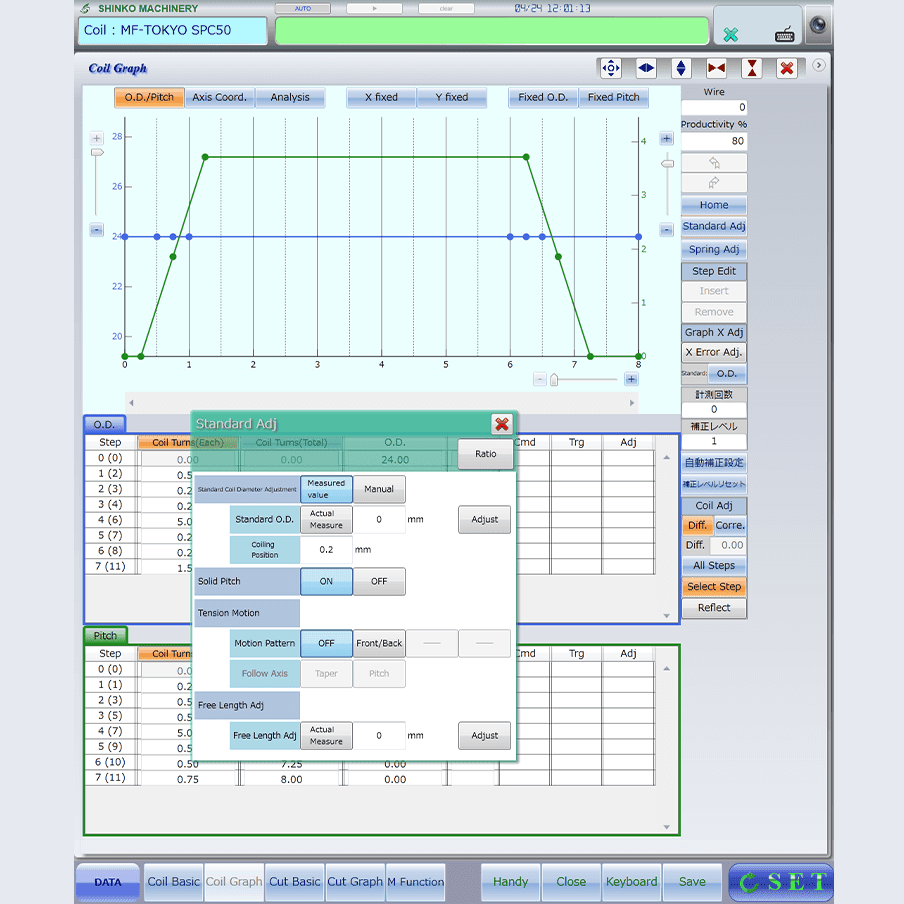

New software for excellent operability

Fine adjustment possibility, automatic adjustment function, and highly intutitive operability contribute to short time programming.