ZF-40

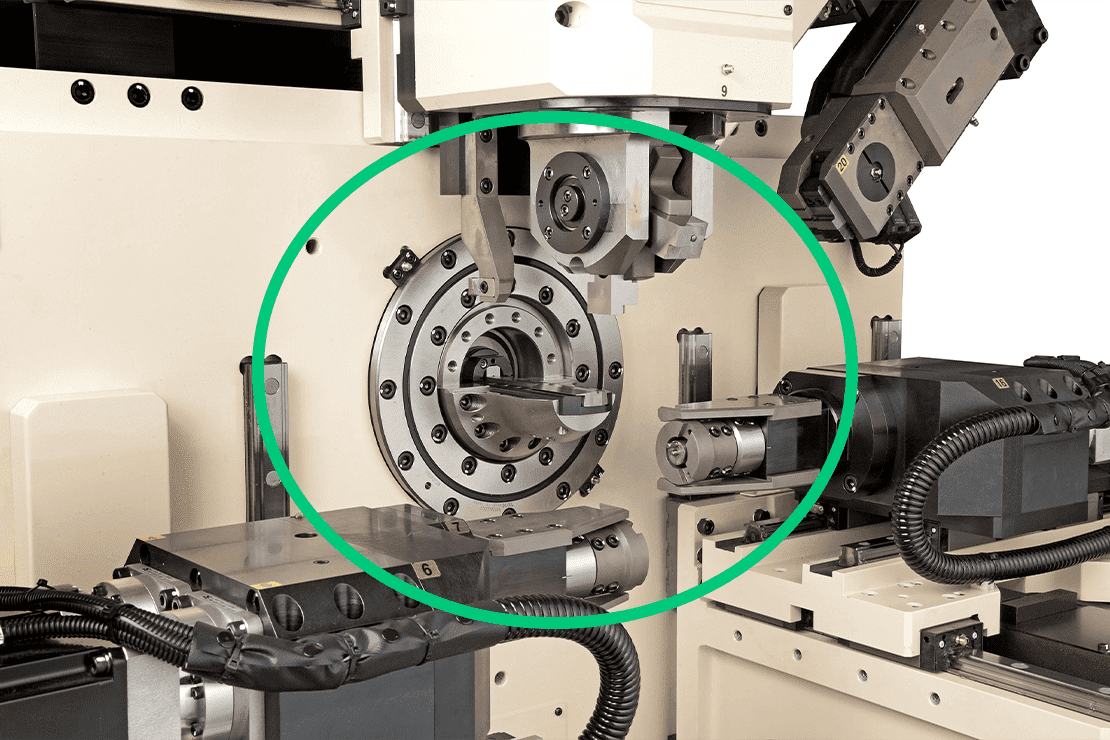

3D units are mounted on upper, right and left sides.

The upper unit has spindle change

and right/left units have w-spindles.

ZF-40 is our flagship model with excellent versatility.

Ultimate torsion spring machine with multi axes and multi functions

- ・Three 3D units with XYZ movement

- ・Spindle changer

- ・W spindle

- ・Advantage for coiling

- ・Wide manufacturing space

- ・Scissor cutting

- ・Easy and functional operation software

SPECIFICATIONS

| Model | ZF-40 |

|---|---|

| Wire Diameter | 1.4mm~4.0mm .055”~.157” |

| Max Feeding Speed | 83m/min |

| Servo Axis |

①Wire Feed, ②Rotary guide, ③Rotary wire ④Left unit inner spindle, ⑤Left unit outer spindle, ⑥Left unit X movement (horizontal) ⑦Left unit Y movement (vertical), ⑧Left unit Z movement (back and forth) ⑨Right unit inner spindle, ⑩Right unit outer spindle, ⑪Right unit X movement (horizontal) ⑫Right unit Y movement (vertical), ⑬Right unit Z movement (back and forth) ⑭Upper unit spinning, ⑮Spindle changer, ⑯Upper unit X movement (horizontal) ⑰Upper unit Y movement (vertical), ⑱Upper unit Z movement (back and forth) ⑱Scissor cutting slide, ⑲Scissor cutting |

| Weight | 3,500kg / 7,777lb. |

| Dimensions |

|

※Specifications can be changed without notice.

FEATURES

Ultimate 4mm torsion machine with three 3D units with XYZ movement

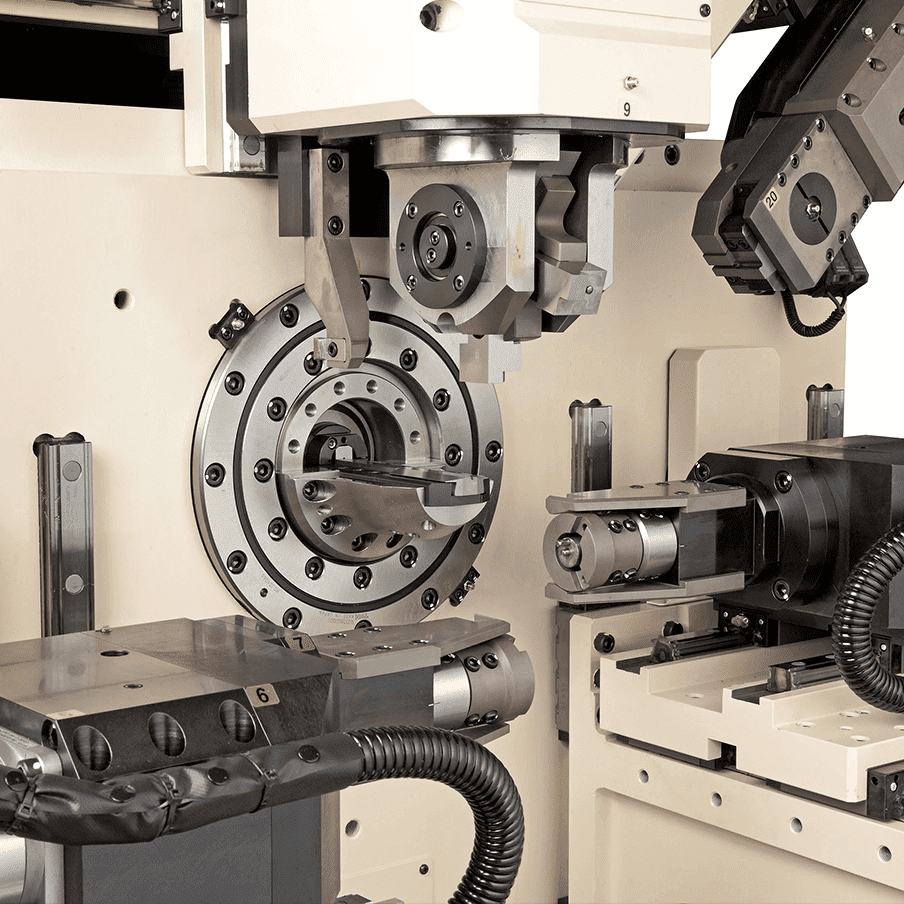

Three 3D units

Three 3D servo-controlled units with XYZ movement.

Not only spindle tools but also bending tools or original manufacturing units can be mounted on each units for versatile spirng making.

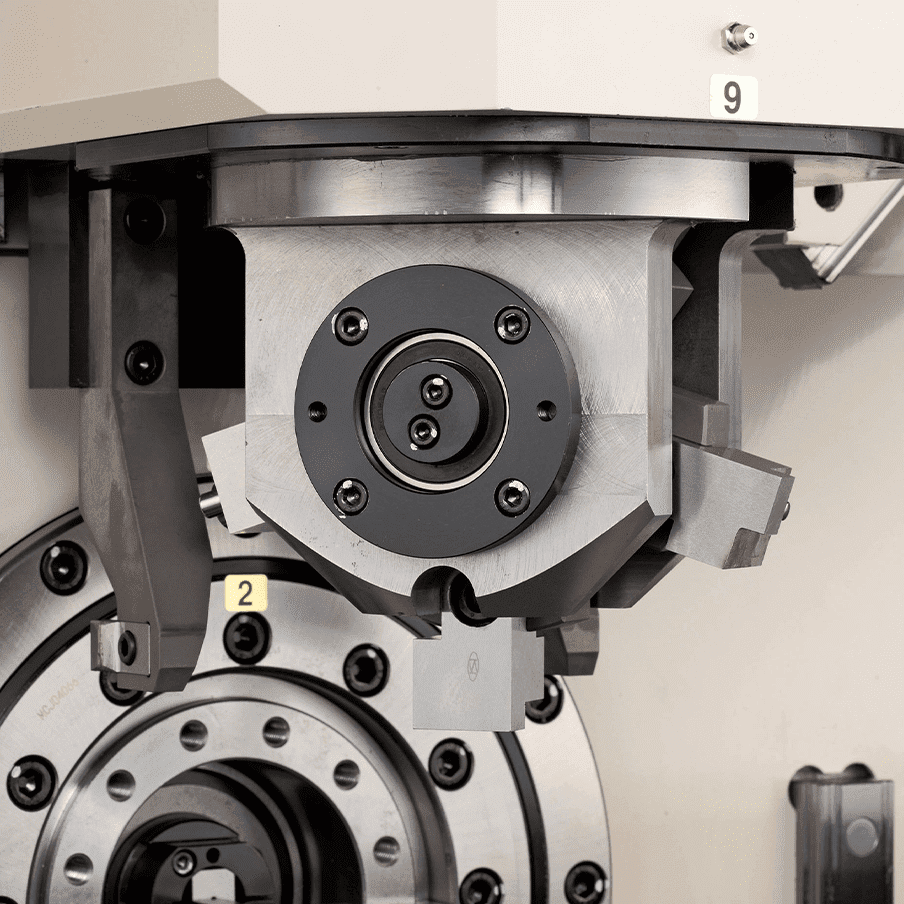

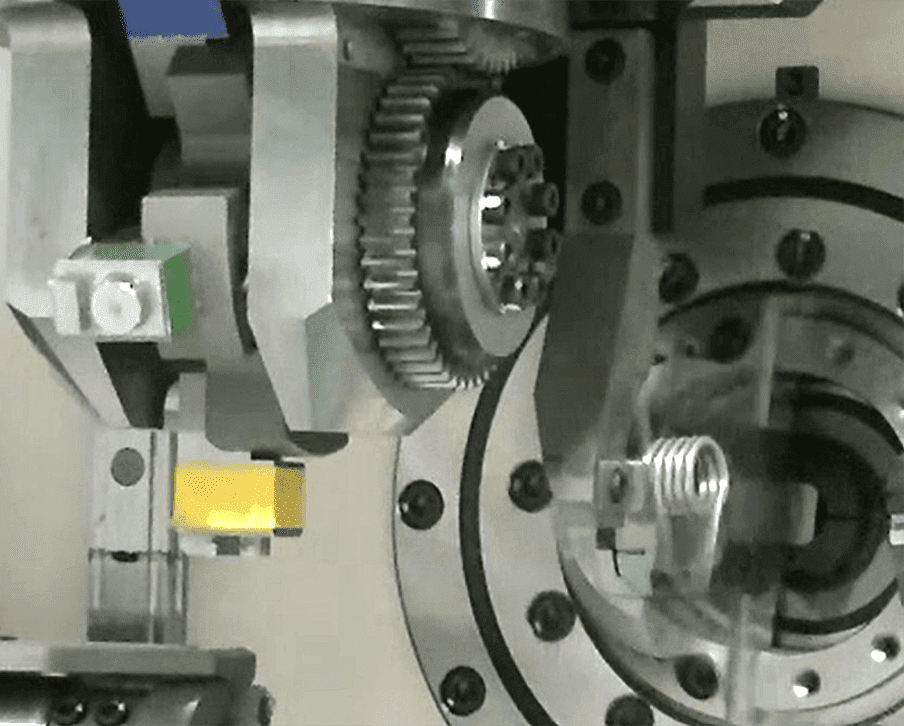

Spindle changer

Spindle changer with 5 spindle tools is mounted on upper unit.

Each of the spindle tools are servo-controlled so that multi-Rs can be made only by the upper unit.

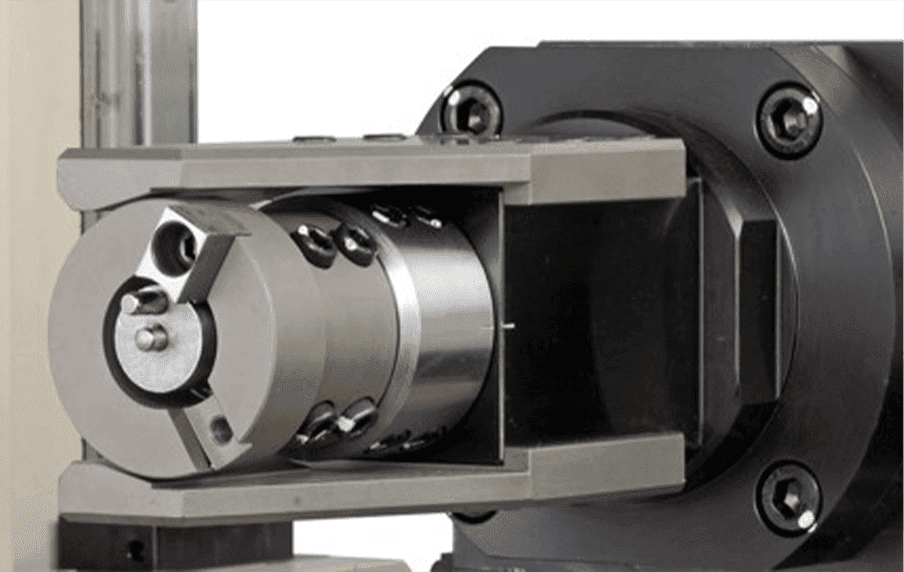

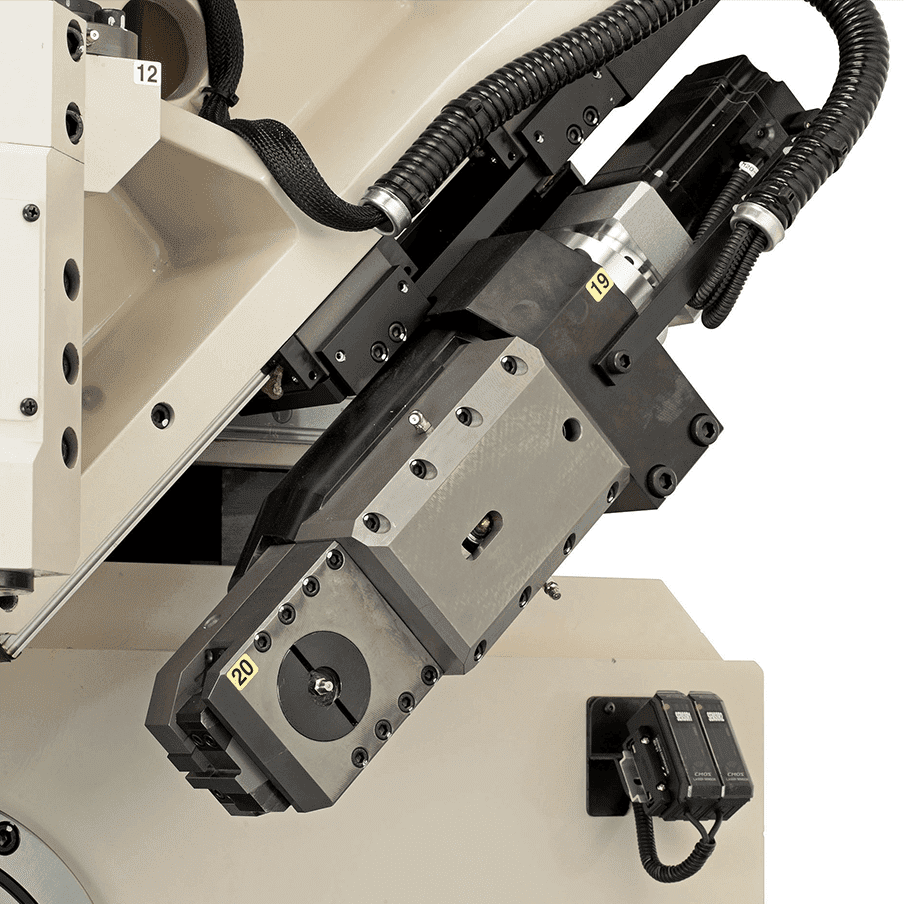

W spindles

W spindles are mounted in right and left units.

Combination of the inner and outer spindles can make multi-R bending and make later bending after cutting by grabbing a spring.

Advantage for coiling

Z (back and forth) movement of upper, right and left units is on the same line of wire feeding, which makes diameter adjustment easy and realize precison coiling.

Z (back and forth) movement of upper, right and left units is on the same line of wire feeding, which makes diameter adjustment easy and realize precison coiling.

Wide manufacturing space

Large stroke and XYZ movement realize wide manufacturing space

by preventing a processed spring from hit machine units.

The wide space works well to make long-hook or long-body-coil spirings.

Scissor cutting unit

Alternative cutting method in addition to slide cutting. You can choose the better way or use both ways according to spring shapes, wire size, etc.

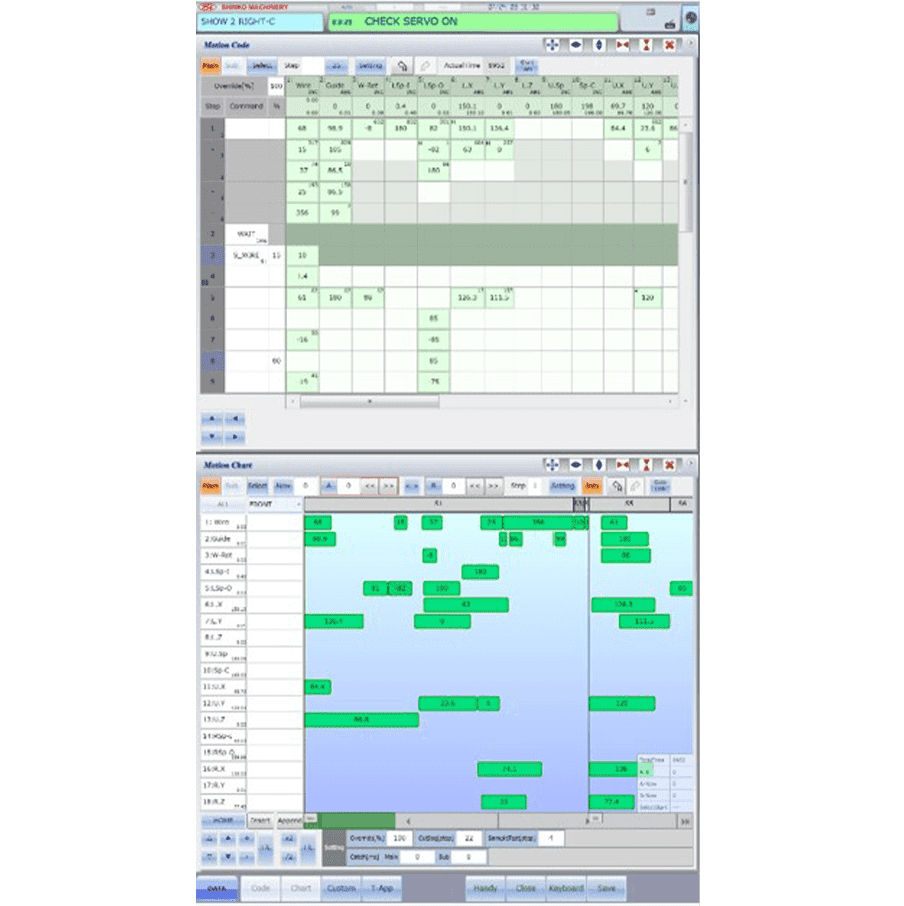

Operational software with excellent functionality and operability

Large touch panel with excellent visuals for good operability

There are two programming methods which are step-by-step programming and axis-by-axis programming (two way). Operator can choose suitable one to make a spring shape or to improve production speed.