MG-100

Versatile coiling functions with 3D torsion attachment

Versatile coiling machine for max. 10mm wire also for 2D torsion springs

- ・Valuable coiling fnctions

- ・Versatility to make 2D torsion springs or to cut wire with straight end

- ・Machine structure to reduce setting time

SPECIFICATIONS

| Model | MG-100 |

|---|---|

| Wire Diameter | 6.0mm〜10.0mm .236”〜.393” |

| Max Feeding Speed | 60m/min |

| Servo Axis |

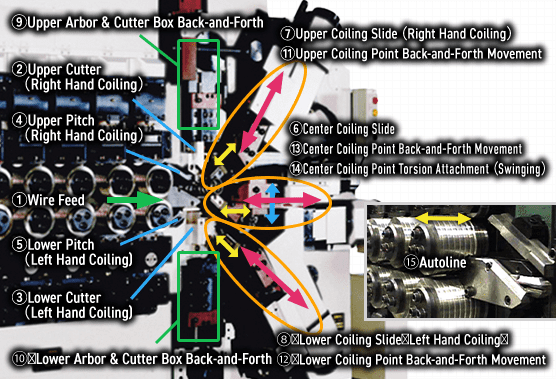

①Wire Feed ②Upper cutter (right hand coiling) ③Lower cutter (left hand coiling) ④Upper pitch (right hand coiling) ⑤Lower pitch (left hand coiling) ⑥Center coiling slide ⑦Upper coiling slide (right hand coiling) ⑧Lower coiling slide (left hand coiling) ⑨Upper cutter and arbor box up and down ⑩Lower cutter and arbor box up and down ⑪Upper coiling point back and forth ⑫Lower coiling point back and forth ⑬Center coiling point back and forth ⑭Center coiling slide torsion attachment ⑮Autoline |

| Weight | 9,500kg / 21,111lb. |

| Dimensions |

|

※Specifications can be changed without notice.

FEATURES

Unique and versatile coiling machine also for 2D torsion springs with precise & durable structure and easy operability

Versatile coiling functions

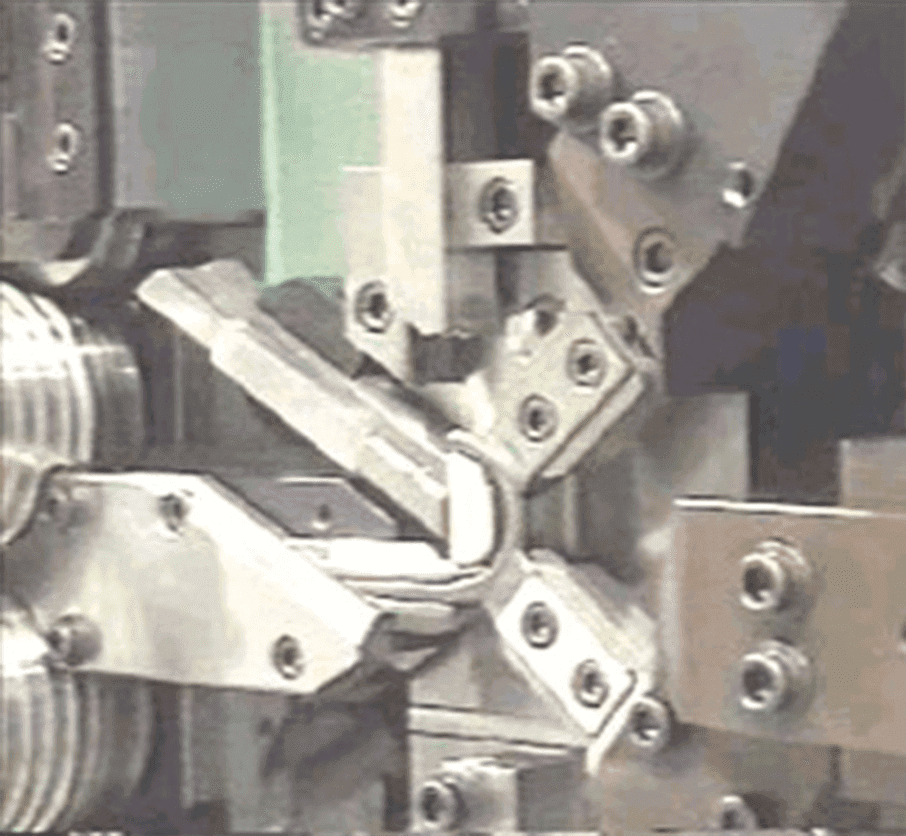

- ・By using 3 slides for right and left coiling, the proper tool positions are maintained against changes in diameter.

- ・The coiling pins can move forward and backward that contributes to highly precise shapes of seats and pitches

- ・Retractable arbor for easy operation for tapered springs and hourglass-shaped springs

- ・No burr cutting by torsion cutting with the upper and lower cutting slides.

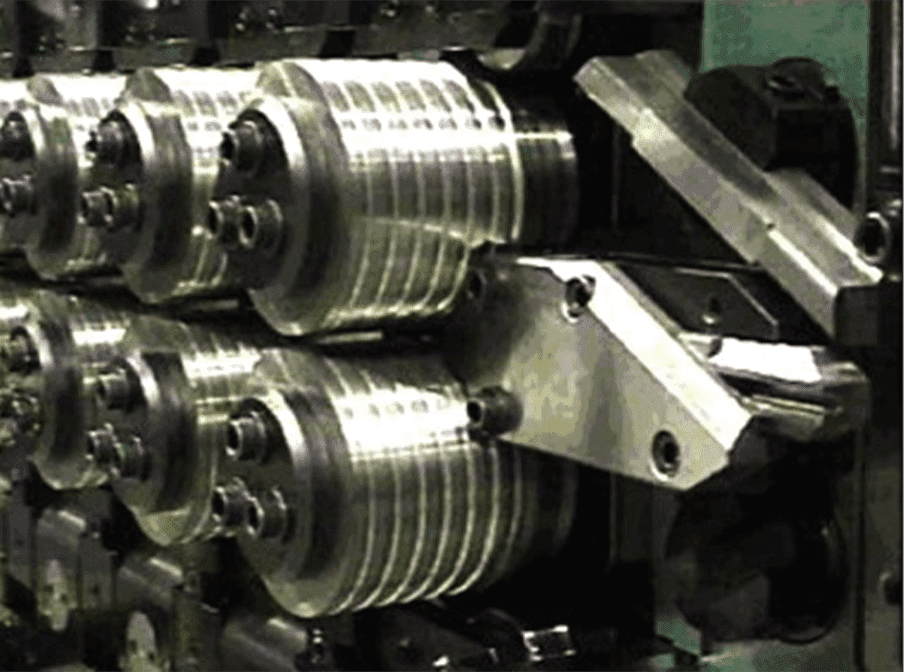

- ・Dispersed wire pressure with six pairs of feed rollers

Versatility to make 2D torsion springs or to cut wire with straight end

- ・Vertical swing of center coiling slide that make remaining straight wire and bending wire possible.

- ・Indivisually controlled retractable upper and lower cutter & arbor units to make tapered springs or to cut wire with straight end.

Structure to save setting time

Setting time is important to small rot prioduction.MG-100 contributes to setting time reduction with the functions below.

- ・Easy positioning of each unit with 15-axis structure

- ・Autoline automatically adjusts feed roller position from 7 grooves.

(No necessity to change feed rollers)